ARREMAD

our expertise

Our areas of expertise in sheet metal work and boiler making, which are used daily to meet your technical requirements, are guaranteed by regular, innovative investments in equipment and team training.

Design

From the design of your parts to the processing of your drawings, our design office will accompany you to make your projects concrete and industrializable.

In co-contracting to understand the requirements of your business, with a concern for eco-design to optimize the implementation, our expertise and our 2D / 3D CAD software, programming and nesting, allow us to provide you with advice and customized studies.

- Processing of 2D/3D files in all formats

- Work on sketches, models, paper plans

- Consideration of technical constraints

- Search for the most suitable solutions and parts

- Validation of specificities

- Layout, programming

- Respect of constraints and deadlines

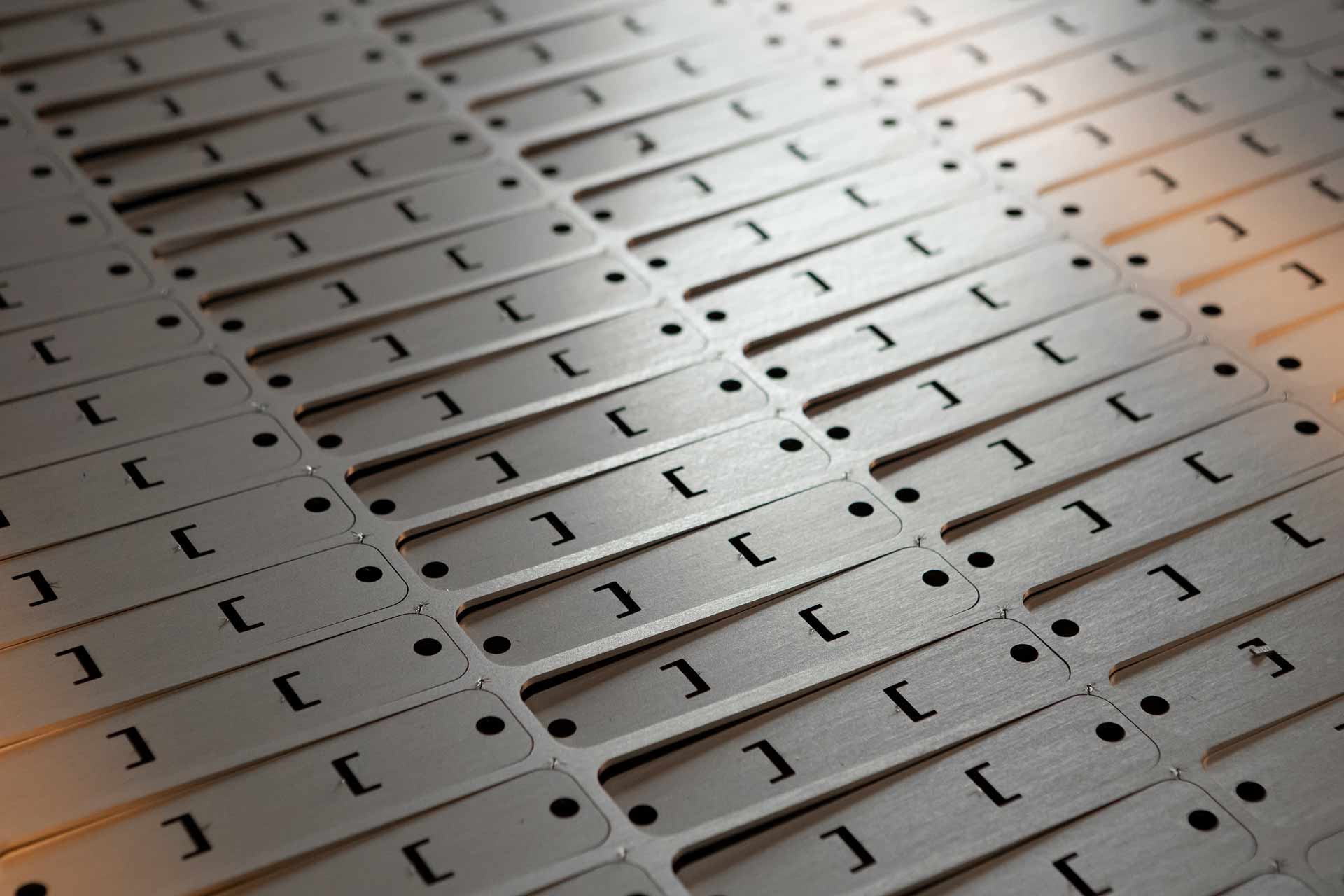

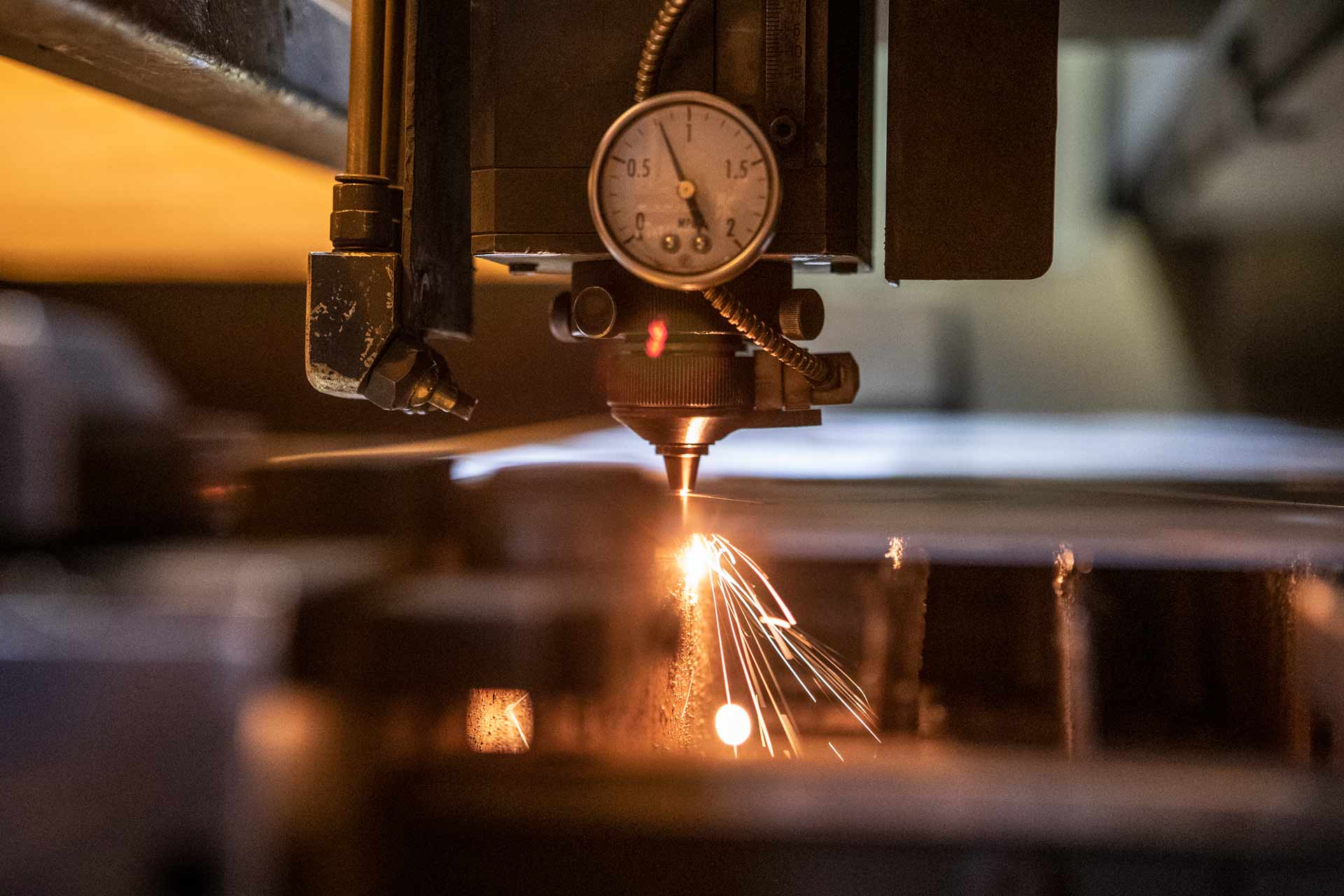

cutting

By shearing, sawing, punching, 2D and 3D laser cutting, engraving, we cut various shapes with a very high precision, a speed of implementation and a quality adapted to your requirements.

Our machine park allows us to produce complex parts through a certified process, in order to provide you with the best service.

machining

Machining is the basic principle of any realization and includes the main manufacturing processes.

We put at your disposal our means in drilling, tapping, threading of tubes… and we ensure, through selected partners, the machining of your more complex parts.

formatting

The know-how of our team associated with the digital programming of our equipment, allow us to realize different types of shaping:

- Folding

- Crunching

- Rolling

- Bending

All this on simple or complex shapes, with a high level of precision and in very competitive deadlines.

assembly

We offer you a tailor-made assembly according to your needs and/or your specifications. Carried out in a dedicated space, with know-how, method and dexterity, our services integrate different techniques:

- TIG welding

- MIG/MAG welding

- Capacitor discharge welding

- Riveting

- Collage

- Screwing

- Assembly of mechanical components

completion

It is the use or the aesthetics of your rooms that will define the need for finishes. On site, or through our network of selected partners, we make it a point of honor to bring you the quality and the desired result through :

- Deburring, sanding, brushing, polishing

- Stainless steel pickling

- Bead blasting

- Sandblasting

- Metallization

- The painting

- Galvanization

- Zinc plating

logistics

At each stage, our logistics team ensures the protection of the parts and the appropriate handling that your request includes:

- Preparation: packing, packaging, kit composition, labeling

- Storage: stock management of your parts and kits produced by us

- Transport: deliveries ensured everywhere in France and abroad by courier, chartering and express